Module name: SVI

Specifications

Ambient Temperature

Maximum temperature:+70℃

Minimum temperature:-50℃

Humidity Level

Maximum average relative humidity

Daily average≤ 95%

Monthly average≤ 90% Altitude: ≤5500M

Seismic scapacity: VIII (seismic intensity)

Water immersion test

24-hour water resistance at a pressure of 0.3 bar

with a voltage of 12 KV.

IP rating

Sealed live part: IP67

Fuse tube: IP67

Metal enclosure: IP4X

Busbar

Internal earthing busbar: 150 mm2Cu

Thickness of insulation bushing: 12.0 mm

Diameter of sealed and insulated busbar: 28.0mm

| No. | Item | Unit | Parameters | |||

| 12kV | 24kV | |||||

| 1 | Rated Voltage | kV | 12 | 24 | ||

| 2 | Rated Current | А | 630 | 1250 | 630 | |

| 3 | Rated Frequency | Hz | 50/60 | 50 / 60 | ||

| 4 | Rated Power Frequency Withstand Voltage 1 min | kV | 48 | 50 | 65 | |

| 5 | Rated Lightning Impulse Withstand Voltage | kV | 85 | 125 | 125 | |

| 6 | Rated Short-time Withstand Current | kA /S | 20/4 | 25 / 4 | 20 / 4 | 20 / 4 |

| 7 | Rated Breaking Current | kA | 20 | 25 | 16 / 20 | 20 |

| 8 | Rated Short Circuit Making Current (Peak) | kA | 50 | 62.5 | 40 / 50 | 50 |

| SVI-12/24 complies with: IEC 62271-200(2011), IEC 62271-1, IEC 62271-100, IEC 62271-102 (2012), IEC 62271-103(2011), IEC 62271-105, IEC 60529; GB 1984-2003, GB 3906-2006, GB 1985-2004, GB 3804-2004, GB/T 11022-1999. | ||||||

The SVI-solid insulated RMU is our newly developed environmentally friendly and high-tech product, which has been researched and developed for two years and seven months with assistance from related national departments. It is suitable for 12kV or 24 kV power distribution systems with the maximum current of 1250A for circuit breaker and busbar. Its performance is more reliable and environmentally friendly than that of traditional SF6 RMU.

The SVI-solid insulated RMU adopts solid insulation technology for switch and busbar system. For example, we use epoxy resin as the dielectric material. This product is suitable for ring main network and radical networks with different connecting solutions. In 2007, it was put into use for the first time.

With the intelligent terminal control unit connected to the solid insulated switches, remote control and monitoring can be realized, ensuring the intelligence, flexibility and reliability of the distribution network.

Features

1. Independent phase to phase isolating technology, each phase and busbar is embedded within epoxy resin and silicon rubber respectively.

2. Compact, light, reliable, intelligent, flexible and safe

3. Environmentally friendly (no SF6 is needed)

4. International patent of our own and original design in China

5. Solid-insulation-embedded pole has been adopted. We use epoxy resin and silicone rubber to achieve complete insulation, and sealing performance. The IP rating reaches IP67 core unit.

In August, 2011, our SVI-solid insulated RMU has been listed in the New Technologies (First Batch) Promoting Plan of the State Grid for its excellent environmental protection performance. In the future, it could completely replace the SF6 RMU.

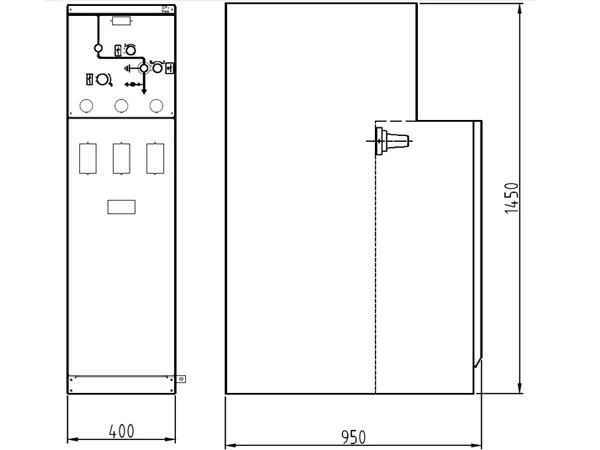

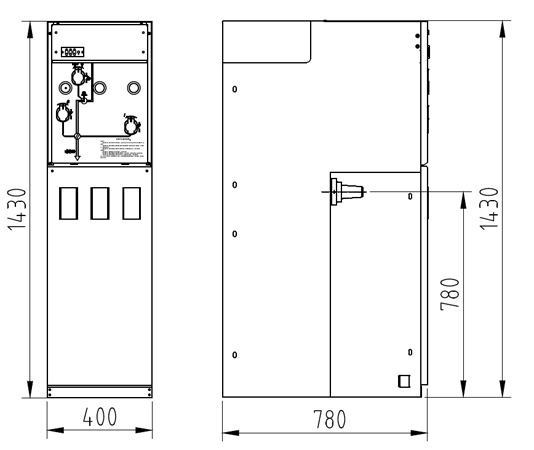

Structure Diagram of SVI Fixed Type SVI-Solid Insulated RMU1. Cable Compartment

2. Viewing Window

3. Circuit Breaker Open Knob

4. Circuit Breaker Close Knob

5. Switch Status(Close and Open)Indicator

6. Energization Indicator

7. Charging Indicator for Circuit breaker

8. Charging Operation Hole for Circuit breaker

9. Disconnector Operation Hole

10. Short-circuit and Earth Fault Indicator

11.Control Box

12. Cable Compartment Viewing Window

Structure Feature

1. SF6 usage is avoided, so the high pressure gas tank is eliminated.

2. All live parts are sealed—the switches are sealed with epoxy resin sheath, while the busbars are sealed with silicon rubber. The whole structure of the SVI-solid insulated RMU is well insulated and sealed. The IP rating reaches IP67.

3. The operating mechanism is completely sealed, resulting in maintenance-free property.

4.Our design separates different phases well, because they are insulated individually. Thus faults between phases can be avoided.

5. Due to the modular design of the products, it is convenient to expand or modify the original solutions, or to exchange modules in the existing solution.

6. Visible working position of each phase of the switch

7. Environmentally friendly, intelligent, flexible

8. Multiple mechanical interlocking functions, highly safe operation

9. We adopt independent phase to phase isolation technology. The product has the maintenance-free property. Two kinds of SVI-solid insulated RMU are available for indoor and outdoor application, respectively.

10. Spring or permanent magnetic control (optional)

11. Arc-protection by independent phase to phase isolation technology

12. FTU or DTD (optional)

Application Advantages Low temperature area.

The SVI-solid insulated RMU doesn’t need SF6. So the potential problem caused by insulation gas being liquefied under low temperature can be avoided.

Plateau area.

Due to the absence of SF6, the problems caused by the big pressure difference between the inside and outside of the gas tank in high altitude areas can be avoided.

Explosion forbidden places.

The switch adopts vacuum interrupter sealed with epoxy resin bushing which can prevent the gas exposure and explosion.

Potential transformer (PT) on-site installing cases.

It is convenient to upgrade the existing RMU.

Basement with workers.

The density of SF6 is 5 times higher than air on the same condition. So if the SF6 in a traditional RMU leaks out, it will accumulate in low area, so the workers there could be harmed or suffocated.

Frequent switching operation situation

Our SVI-solid insulated RMU can endure more than 10,000 times of switching operations.

Areas with high requirements for environmental protection.

Our solid insulation RMU doesn’t contain SF6, which is a kind of greenhouse gas.

Coastal area.

The well sealed mechanism and professional high salt mist tester can ensure the long service life in costal area.

Windy and sandy area.

The IP rating of the SVI-solid insulated RMU reaches IP67. The control loop compartment is specially treated, so our product can work in windy and sandy area for a long time.

Power Distribution network automation.

The build-in SOJO electric SJDA2000 power distribution automation products or other optional products lead to automatic power distribution. The loading switches can switch off in a extremely short period of time, contributing to the power distribution automation.

Performance

Safety

1. The SVI-solid insulated RMU doesn’t need SF6, so the reduced insulating performance and arc quenching ability caused by low gas pressure in SF6 insulated RMU could be avoided.

2. Complete insulating structure between different phases can avoid explosion accidents caused by interphase short circuit.

3. The vacuum interrupter makes our product more reliable and environmentally friendly than oil insulation and SF6 gas insulation techniques do. The epoxy resin bushing outside the switch provides additional protection.

4. Visible working position of each phase of the switch makes the operation, inspection and repairing of the machine highly convenient.

5. Water immersion test has been conducted, and the result shows that all the parameters we measured after 24h operation under 0.3 bar pressure in water meet related requirements.

6. Complete tests before and after the pouring of the switch bushing are conducted. The partial discharge is less than 5 PC. The vacuum arc quenching chamber we adopted is from a well known domestic company.

7. The switch brushing has been subjected to thermal shock test. Soft fillings are added between the switch brushing and the vacuum switch to avoid the breaking stress caused by thermal expansion. Thus brushing won’t get any cracks during the long-term running of our SVI-solid insulated RMU.

8. The high glass transition temperature of the epoxy resin and silicone rubber gives stable insulating performance at high temperature.

9. We don’t use chains in the transmission part, so the reliability is enhanced.

10. The product is examined by the People’s Insurance Company (group) of China (PICC). The reliability has been approved and insured. Each incident is insured with maximum 0.9 million RMB, guaranteeing our clients’ benefits.

11. SF6 decomposition caused by various reasons can reduce the arc quenching ability which may lead to SF6 enclosure explosion. However, this potential risk is eliminated because our RMU doesn’t need SF6 at all.

12. The SVI-solid insulated RMU adopts consolidated epoxy resin blocks as the external protection, while the space between epoxy resin block and vacuum interrupter is filled with solid dielectric material to ensure the vacuum condition and insulating ability. The pressure of vacuum interrupter is below the atmospheric pressure. Thus the explosion risk is reduced to a low level.

13. Centrally located insulation blocks are the core components of solid dielectric RMU. The three position vacuum arc quenching chamber is insulated by solid insulating material. The insulation and vacuum interrupter are integrated. Each phase is separately insulated and sealed with epoxy resin. The insulation blocks use American epoxy resin GE, inter-phase discharging is well prevented.

14. Covered blocks keep the vacuum interrupter surface away from ambient pollution, such as condensation, dirt, and other pollution, so the fault risks can be reduced.

| Item | SF6 RMU | SVI-Solid Insulated RMU | Comparison |

| Rating | 630A 12kV | 630A 12kV | Identical |

| Structure | Three phases, integrated | Three phases, independent | SVI-Solid insulated RMU has no potential problem of phase to phase short-circuit fault |

| Operating Mechanism | Three phases, integrated | Three phases, integrated | Identical |

| Arc Quenching Method | SF6 | Vacuum | Increased mechanical life of switching operation for SVI-solid insulated RMU |

| Insulation | SF6 | Epoxy Resin | Increased insulating capacity and reliability. No leakage test is needed |

| Earthing | Three phase, integrated | Three phases, independent | Operated individually |

| Size (4 panels) | 1460 ×823 ×1409 | 1640 ×750 ×1143 | SVI-Solid insulated RMU is 20% smaller |

Environmental Protection

According to the Kyoto Protocol, SF6 is one of the six kinds of greenhouse gas. In China, it has been listed in the National Hazardous Wastes List since 1998.

The global warming potential of SF6 is 23,900 times that of CO2. Statistically, more than 4,500 tons of SF6, just equals to 120 million tons of CO2, is consumed every year in the power distribution system.

Additionally, the lifetime of SF6 in atmosphere is about 3,400 years, affecting hundreds generations of human beings, way more serious than CO2. In resent years, studies show that the SF6 concentration has been ascending rapidly, causing more and more attention in the international community.

However, our RMU doesn’t need any SF6 at all. So the environmental protection performance is excellent.

Flexibility

It is convenient to expand, exchange and modified the original solutions, so clients can connect the power and upgrade the solution on site.